Fabric Tensile Strength Tester: Measuring Durability and Performance

Fabric tensile strength testing is a critical process in the textile industry, ensuring that materials meet specific strength and durability standards. This testing evaluates a fabric’s ability to withstand tension until it breaks, providing essential data for manufacturers, quality control laboratories, and researchers. The primary instrument used for this purpose is the fabric tensile strength tester.

Understanding Fabric Tensile Strength

Tensile strength refers to the maximum force a fabric can endure while being stretched before it tears or breaks. This property is vital for determining a fabric’s suitability for various applications, from clothing to industrial materials. Factors influencing tensile strength include fiber type, yarn structure, fabric weave, and finishing processes.

Types of Tensile Strength Tests

Several standardized methods assess the tensile strength of fabrics:

- Grab Test (ASTM D5034): This method measures the breaking force and elongation of fabrics using a specific width of the specimen, clamped in the center part of the fabric. It’s commonly used for woven textiles.

- Strip Test (ASTM D5035): In this test, a fabric strip of defined width is clamped and subjected to tension until it breaks. This method provides insights into the fabric’s strength across its entire width.

- Tongue Tear Test (ASTM D2261): This procedure determines the force required to continue a tear in a fabric, simulating real-world scenarios where fabrics might be subjected to tearing forces.

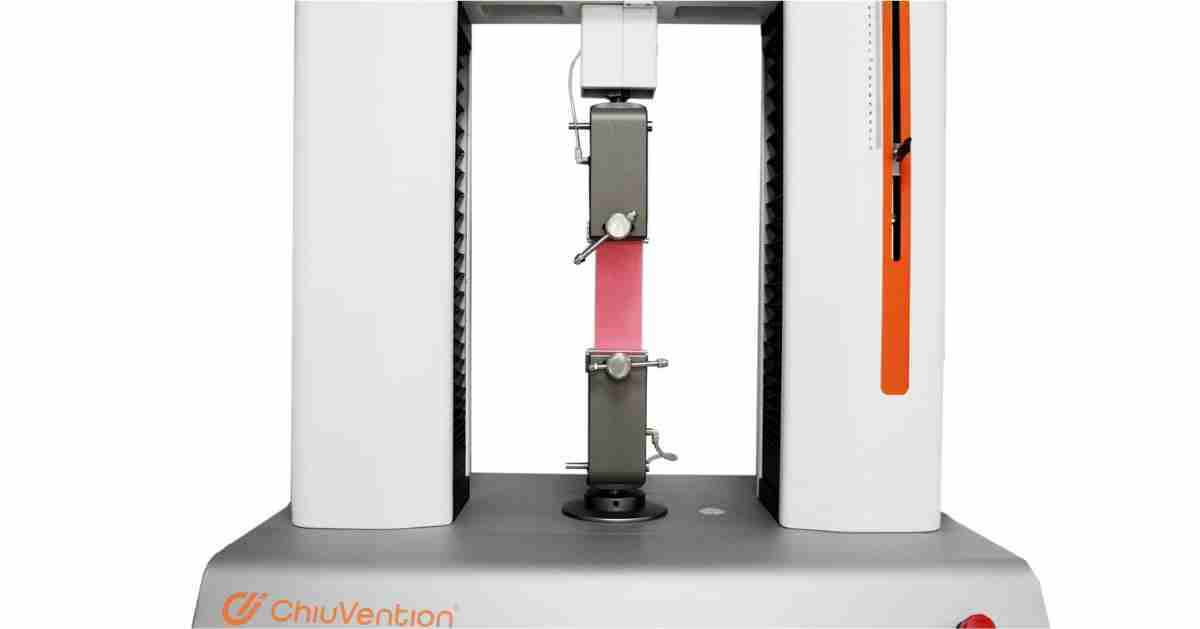

Fabric Tensile Strength Tester: An Overview

A fabric tensile strength tester is a specialized machine designed to perform the above tests accurately and consistently. Key features of these testers include:

- Load Cells: Sensors that measure the force applied to the fabric specimen. High-quality testers use precise load cells to ensure accurate readings.

- Grips and Clamps: These hold the fabric specimen securely during testing. Different grips are available to accommodate various fabric types and test methods.

- Control Systems: Modern testers are equipped with computerized controls that allow for precise setting of test parameters, data collection, and analysis.

- Crosshead Movement: The part of the machine that moves to apply tension to the fabric. Controlled movement ensures consistent application of force.

Testing Standards and Compliance

Adherence to international standards is crucial for ensuring test reliability and comparability. Some of the widely recognized standards include:

- ASTM D5034: Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test).

- ASTM D5035: Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method).

- ISO 13934-1: Tensile properties of fabrics — Part 1: Determination of maximum force and elongation at maximum force using the strip method.

Manufacturers and laboratories must ensure their equipment and procedures align with these standards to maintain quality and consistency.

Applications of Tensile Strength Testing

Understanding the tensile strength of fabrics is essential across various sectors:

- Apparel Industry: Ensures garments can withstand daily wear and stress without tearing.

- Technical Textiles: For products like seat belts, parachutes, and industrial filters, high tensile strength is critical for safety and functionality.

- Medical Textiles: Materials used in medical applications, such as surgical gowns and drapes, require specific tensile properties to ensure performance and safety.

Advancements in Tensile Testing Equipment

Recent developments have enhanced the capabilities of fabric tensile strength testers:

- Digital Integration: Modern machines feature digital interfaces and software that allow for real-time data analysis, storage, and reporting.

- Automation: Automated testing procedures reduce human error, increase throughput, and provide more consistent results.

- Versatility: Advanced testers can perform multiple types of tests, including tensile, tear, and burst tests, making them versatile tools for quality control.

Selecting the Right Tensile Strength Tester

When choosing a fabric tensile strength tester, consider the following factors:

- Test Requirements: Identify the specific tests you need to perform and ensure the machine supports those methods.

- Material Range: Ensure the tester can accommodate the types of fabrics you work with, considering factors like thickness and elasticity.

- Accuracy and Precision: Look for machines with high-quality load cells and precise control systems to ensure reliable results.

- Compliance: Verify that the tester meets relevant international standards to ensure test validity.

Conclusion

Fabric tensile strength testers are indispensable tools in the textile industry, providing critical data on material performance. By understanding and utilizing these machines effectively, manufacturers and researchers can ensure their products meet the necessary strength and durability standards, leading to higher quality and more reliable textile products.

Fabric tensile strength testers are essential instruments in the textile industry, designed to evaluate the strength and durability of various fabrics. By measuring the force required to elongate and ultimately break a fabric sample, these testers provide critical data that inform quality control, product development, and compliance with industry standards.

Understanding Fabric Tensile Strength

Tensile strength refers to the maximum force a material can withstand while being stretched before breaking. In textiles, this property is crucial as it determines the fabric’s ability to endure mechanical stresses during usage. Factors influencing tensile strength include fiber type, yarn structure, fabric weave or knit pattern, and finishing processes.

Methods of Testing Fabric Tensile Strength

Several standardized methods are employed to assess the tensile strength of fabrics:

- Grab Test (ASTM D5034): This method involves gripping the fabric sample in the center portion, leaving the edges free. It provides an overall assessment of the fabric’s tensile properties, accounting for fabric imperfections and variations.

- Strip Test (ASTM D5035): In this approach, the entire width of the fabric sample is gripped, providing a more uniform stress distribution across the specimen. This method is particularly useful for comparing the tensile properties of different fabrics.

- Trapezoid Test (ASTM D5587): This test measures the tearing strength of fabrics by applying force to a notched specimen, simulating real-life scenarios where fabrics may be subjected to tearing forces.

Components of a Fabric Tensile Strength Tester

A typical fabric tensile strength tester comprises the following components:

- Load Cell: Measures the force applied to the fabric specimen.

- Grips or Clamps: Secure the fabric sample in place during testing.

- Crosshead: Moves to apply tension to the fabric, controlled at a constant rate.

- Control System: Manages test parameters and records data for analysis.

Significance of Fabric Tensile Strength Testing

Conducting tensile strength tests on fabrics offers several benefits:

- Quality Assurance: Ensures that fabrics meet specified strength requirements, reducing the risk of product failure.

- Product Development: Assists manufacturers in selecting appropriate materials and processes to achieve desired fabric properties.

- Compliance: Verifies adherence to industry standards and regulations, facilitating market acceptance and consumer trust.

Advanced Features in Modern Testers

Contemporary fabric tensile strength testers incorporate advanced features to enhance testing accuracy and efficiency:

- Digital Control Systems: Allow precise setting of test parameters and real-time monitoring.

- Automated Data Analysis: Software integration enables comprehensive analysis and reporting of test results.

- Versatility: Capability to perform various tests, including compression, bending, and tearing, on different materials.

Conclusion

Fabric tensile strength testers play a pivotal role in the textile industry by providing essential data on fabric performance. Understanding and utilizing these instruments effectively contribute to the production of high-quality, durable textile products that meet both industry standards and consumer expectations.

Universal Tesile Testing Machine;Tensile Strength Tester;Tensile Testing Machine

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk